The Process

1,000 Hours of Mastery

Creating a single-crystal diamond ring is an extraordinary journey that transforms raw carbon into wearable art through patience, precision, and uncompromising dedication to excellence.

Stage One

Crystal Growth

The journey begins in a precision-controlled laboratory where carbon atoms are arranged into a perfect crystal lattice structure. Using either CVD (Chemical Vapor Deposition) or HPHT (High Pressure High Temperature) methods, we grow large diamond plates over approximately 5 weeks.

- Temperature controlled to within 0.1 degrees

- 24/7 monitoring for structural integrity

- Starting size: 50+ carats

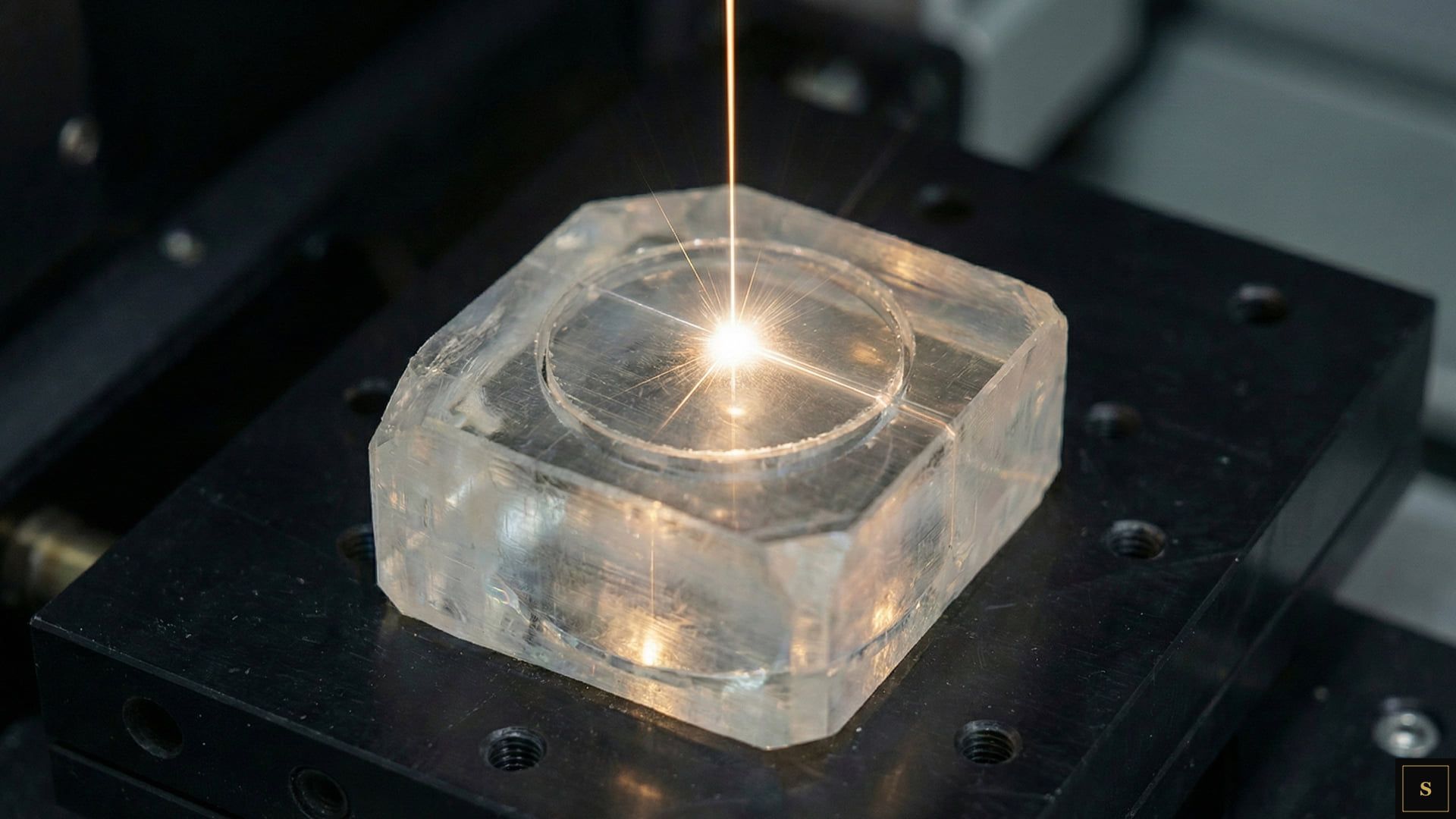

Stage Two

Laser Cutting

Using state-of-the-art laser technology, the rough ring shape is cut from the diamond plate. This is one of the most critical stages — a single miscalculation can shatter months of work into worthless fragments.

- Micrometer precision cutting

- Computer-guided for absolute accuracy

- Zero margin for error

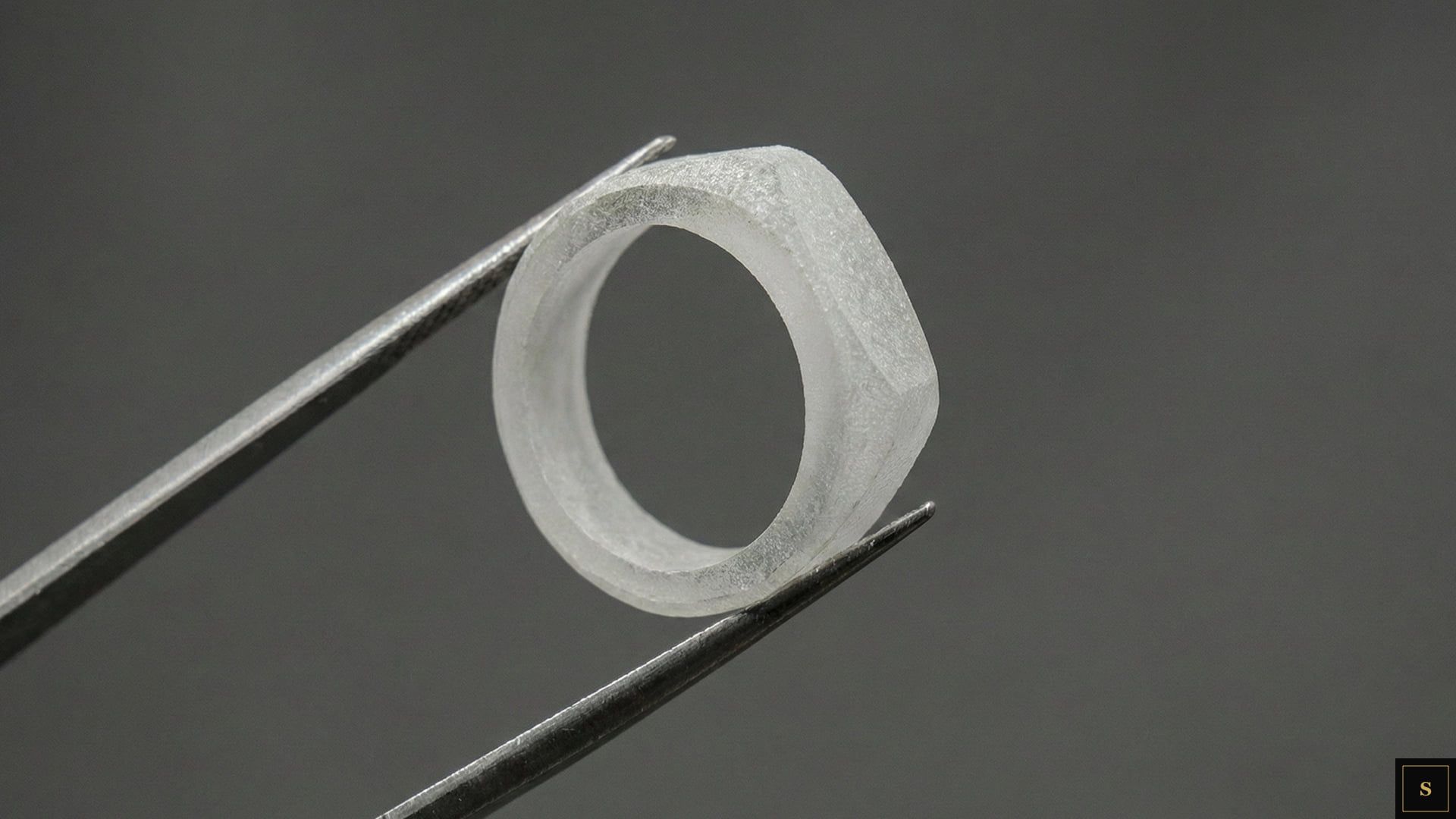

Stage Three

Pre-Grinding

The rough-cut ring undergoes 300+ hours of grinding to achieve the basic shape. Diamond grinding wheels carefully remove material to create the inner and outer ring profiles.

- 300+ hours of precision grinding

- Diamond-on-diamond grinding

- Creating perfect ring profile

Stage Four

Hand Polishing

The most time-intensive stage requires 750+ hours of meticulous hand polishing. Master artisans use traditional lapidary techniques to achieve mirror-like surfaces on both inner and outer surfaces of the ring.

- 750+ hours of hand polishing

- Traditional lapidary techniques

- Mirror-finish perfection

Stage Five

Faceting

Each ring receives 118+ precisely calculated facets — more than double the 57 facets of a standard brilliant cut diamond. Every angle is computed for maximum light return and fire, creating unprecedented brilliance.

- 118+ precision facets per ring

- Computer-calculated angles

- Maximum brilliance and fire

Stage Six

Certification

Every completed ring is submitted to GIA or HRD Antwerp for independent grading and certification. The ring receives a comprehensive report detailing its 4C grades, dimensions, and a unique laser inscription for authentication.

- Independent third-party grading

- Full 4C grading report

- Unique laser inscription

Experience the Result

Witness the culmination of over 1,000 hours of craftsmanship. Each ring in our collection represents this extraordinary journey.